We’re often asked why power quality is a part of an online (energized) motor test. It is important to understand that the PQ test of an energized motor test is only a snapshot of the overall power quality present at that motor. If a facility suspects they have widespread power quality issues, an energized motor test isn’t going to give them all the answers they need. We can provide a deeper, more comprehensive power quality analysis if that’s what’s needed. If you are doing motor testing you should also consider investing in power quality analysis equipment, both fixed and portable instruments.

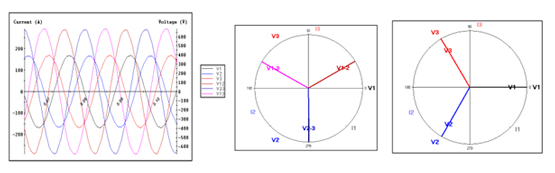

The power system determines the quality of the voltage, and the powered load is what will most impact the quality of the current. This is due to the lead/lag relationship between voltage and current. We will not go into depth on that topic here.

Let’s start with low voltage first. If we have a lower voltage delivered to an operating motor than it is rated for, the performance of the motor is impacted. Many people consider only rotational speed, but torque is also impacted. Torque on an induction motor is based on the applied voltage squared. If I’ve got a motor rated for 480VAC and I’m low by 10%, my torque isn’t merely reduced by 10%, it’s reduced by nearly 20%. High voltage is generally more easily tolerated by most induction motors, up to about 105% of the rated voltage. Beyond this level, however, we can see an increase in the full load amps (FLA) of the motor. What happens as amps go up? Heat goes up. What’s the enemy of electric motors? Heat.

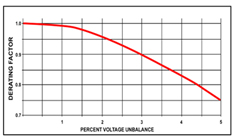

We also don’t want to see voltage imbalances in power applied to a motor. These imbalances usually require a motor to be de-rated.; NEMA MG-1 has a table of recommended de-rating factors for voltage imbalances. A study performed by the Electric Power Research Institute (EPRI) suggests that a voltage imbalance can increase winding temperatures by as much as 25%. As stated above, we don’t want that. Further, a voltage imbalance of up to 5% can drive a de-rating of 75% of a motor’s rated horsepower. The MG-1 suggests that with voltage imbalances above 5% the motor not be operated at all.

Current imbalances often are a result of an increase in electrical resistance in the motor circuit. A more conclusive indicator is both a voltage and current imbalance together. A good rule of thumb is that if the measurement is performed upstream of the high-resistance connection, only a current imbalance will be detected. If the measurement is taken downstream of the high resistance connection, both voltage and current imbalance will be present.

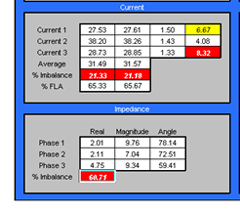

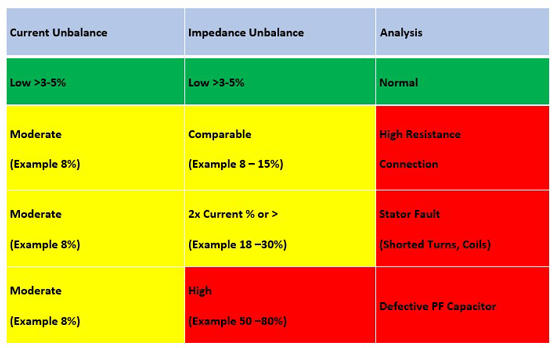

When measuring phase currents on Wye connected motors (Series) current will be the same regardless of where measured in each phase. What to look for is unbalance between the phase measurements indicating a resistance or reactance issue in one of the phases. Then look at impedance and determine the level of unbalance. If it is comparable to the current unbalance, you have a resistance issue, if impedance is double the current unbalance, then you have winding issues. With extreme impedance unbalance as compared to current, look for open power factor correction capacitors.

The table above displays a current and impedance unbalance ratio indicative of defective power factor correction capacitors.

The PQ test is an important part of an energized motor test. Don’t skip this step just because it’s accepted that power quality is poor at a facility. If in fact it is, we need to understand the impact on the motors we test.