Cargill, Inc. had been using its insurance company to conduct infrared inspections for more than ten years. Derek Roth, Reliability and Maintenance Leader at Cargill, knew that these inspections were focused on looking for imminent failures instead of on defect elimination. He knew that infrared thermography could be used much more effectively as part of a comprehensive predictive maintenance program that included cause analysis and reporting.

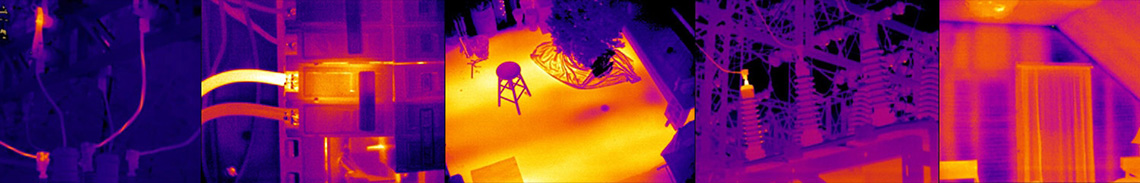

In 2005, The Snell Group began conducting regular electrical and mechanical infrared inspections and online and offline motor circuit analysis inspections at Cargill. According to Derek, “The value of these technologies, as part of a comprehensive predictive maintenance program, is catching defects early when they are small problems that we can fix on our schedule, as opposed to on ‘the equipment’s schedule’. Using The Snell Group to provide both infrared and motor circuit analysis inspections prevents downtime and collateral damage.”

Derek knows that the inspection program is working because of the number of problems that are found and then fixed on a regular maintenance schedule. One example is when an MCA inspection revealed an insulation breakdown that if left undetected would have seriously damaged a 200 horsepower motor in just a few more weeks.