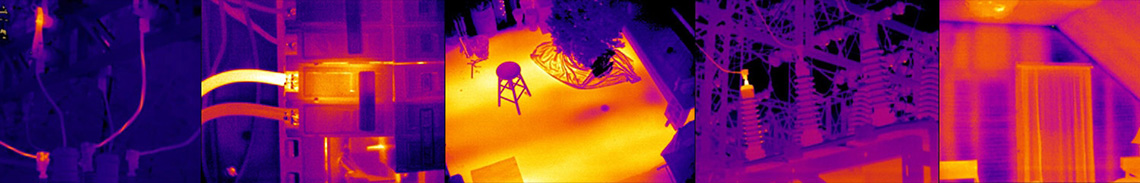

Cargill, Inc., an international provider of food, agricultural and risk management products and services, rigorously adheres to a proactive maintenance reliability model in order to save money by identifying potential failures and assessing risk before the failure occurs. The company knows the criticality of all its on-site assets and monitors critical assets on a proactive, regular schedule. Under the direction of John Bigelow, the Maintenance and Reliability Leader at Cargill Grain and Oilseeds North America, The Snell Group provides regular, scheduled infrared inspections for electrical and mechanical assets as well as motor circuit analysis.

Cargill and The Snell Group worked together to determine which assets were critical, conducted risk assessments and established testing routes. Based on the assessments, they developed a schedule for regular electrical and mechanical infrared inspections and motor testing. With established routes and schedules, the M&R Leader knows that the facility’s many thousands of critical on-site assets are proactively monitored.

According to John Bigelow, The Snell Group’s services are paying real financial returns in reduced downtime costs. “The IR mechanical inspection reports are always full of surprises about potential failures that we wouldn’t otherwise have detected until they failed. In one instance, the IR scans clearly revealed significant sheave problems with some of our machines that were not being reported through the conventional PM process. This failure mode was causing significantly reduced belt life and was impacting quality results.”

Motor testing has also proved valuable to the company. One example is the lesson learned about storing spare motors. In John’s words, “We were storing our critical spare motors in an exposed area that was not climate controlled. When we tested them, we found that 80% had defects and would fail prematurely. With this data, it was clear that we needed to construct a building for storage. After repairs and storing the spare motors in the new space, follow-on testing indicated that the number of failed motors was significantly reduced. We discarded those critical spares that did not pass testing and that were providing us a false sense of security. Installing a critical spare motor and then suffering premature failure of that spare would have had real financial impact. I have complete trust and confidence in The Snell Group’s knowledge and skills to provide these services effectively. This is undoubtedly a wise investment.”