Thermal imaging opens the eyes of management to the hidden problems within their factories, but if caught in time can save hundreds of thousands to their bottom line.

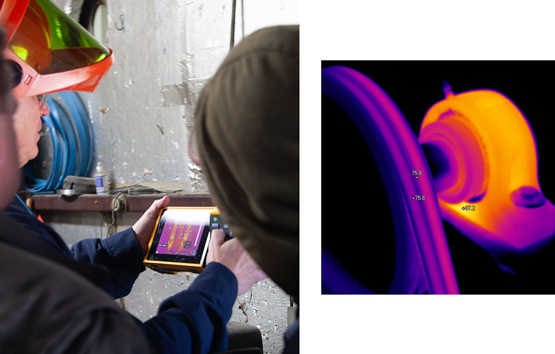

Thermography is the process of using a specialized, electronic infrared camera to detect thermal radiation (heat) emitted by an object. The technology allows skilled thermographers to locate thermal anomalies—abnormal patterns of heat invisible to the eye—that indicate possible failure modes, faults, defects or inefficiencies within a system or material.

Remarkable information can be extracted from thermal images and interpreting the findings can be complex. To ensure quality, improve safety and meet insurance requirements, the infrared services from Snell Inspections provide a one-stop shop from which you can have a complete infrared PdM program.

What systems of yours are most likely to fail?

Many facilities take advantage of Snell Inspections IR consultants for special applications, equipment commissioning, and new program setup. The cost of preventing failures in electrical systems is often astronomical and our services can quickly ramp up an effective infrared program.

Infrared Thermography enables corporations to reduce the risk of unscheduled downtime.

Increase Up-time!

Data centers rely heavily on the health of their primary electrical system, as well as their Uninterruptible Power Supply (UPS) systems for back-up in the event of a power loss. Any downtime from an outage can cause a loss of asset availability and generate big financial losses. IR inspection is successfully used to check for electrical problems that, if not detected, could cause costly downtime.

Reduce Risk

Large electric utilities use thermal imaging to monitor bushing connections on transformers carrying power from their primary generator. An unplanned shutdown due to failure of these components will have catastrophic costs and consequences. With frequent monitoring plants can accurately evaluate the situation and take corrective action to manage problems.

Conserve Energy/Save Money

High costs of conditioning buildings are a concern in residential, commercial buildings, and institutions. Energy auditors and state weatherization groups use thermal inspections regularly to evaluate existing structures and make them more efficient. Quickly locate thermal patterns showing the presence of insulation voids and excessive air leakage. Diagnose problems with your HVAC systems to conserve energy, improve comfort and health, and save money.

A few examples of infrared thermography applications:

- Electrical Systems – Detect faulty electrical connections or overloaded circuits. Manufacturing processes are dependent on electrical energy, a failure can cost tens of thousands of dollars for every minute down. Find and scheduled repairs before they fail.

- Mechanical Equipment – Infrared can locate abnormally warm motors or possible bearing failures. It is a powerful tool for assessing the condition of motor assets, allowing for confirmation and advance warning of problems prior to failure.

- Fluid Systems – Thermal imaging can find line blockages, storage tank levels, diagnose heat exchangers or pipe temperatures. Knowing the basics of heat transfer, diagnostic problem solving with fluids is remarkable and the returns immense.

- Building Applications –Verify insulation placement, locate missing insulation, test insulation performance, find air infiltration, and detect moisture or moisture damage. Reveal problems not typically detected with traditional (sometimes destructive) testing methods.

- Low-Slope Roofs – The cost of premature failure and reduced life cycle in roofs is staggering and the cause is most often trapped moisture. Under the right conditions, thermography can readily detect wet roof insulation leading to system failure.

- Nondestructive Testing – Many industries, such as aerospace, have grown to rely on lightweight composite materials. Any defects can render these materials dangerously weakened. Thermal techniques can be employed to locate de-lamination and moisture.

Your needs will determine inspection frequency, from routine quarterly to full-time condition monitoring assistance. We can give guidance on effective report writing, establishing proper inspection routes, implementing appropriate procedures, and establishing best safety practices.

With a strong emphasis on safety, our consultants are up to date on the NFPA 70E, STANDARD FOR ELECTRICAL SAFETY IN THE WORKPLACE (2024) and OSHA standards that are required yearly. To learn how our infrared inspections can get a save you money or if you’d like to integrate thermography into your overall PdM/Condition Monitoring programs, please contact us.