Motor tester manufacturer training and independent vendor theoretical training are generally quite different. Over the years I am certain that you have heard the phrase, “You get what you pay for.” There is a lot of truth in that short phrase. Whenever you purchase a product it pretty much goes without saying if you buy the cheaper one, it is of lesser quality, prone to problems, and will not attain the longevity of the higher quality product. When it comes to testing equipment; in particular, motor test equipment, “You get what you pay for,” is true not only with the product but also with subsequent training.

Motor test instruments are becoming common equipage items at numerous commercial and industrial facilities worldwide. Having these very capable instruments is only part of the equation. Not understanding the full capabilities of these equipment’s as well as the operational theory of the motors and circuitry that they can test, will seriously limit your program's overall effectiveness.

Motor vendors generally provide training as part of the initial purchase cost of a test instrument or offer training as a separate cost. Some offer advanced data analysis training. In most cases, initial vendor training spends considerable time on software and operation of their respective tester and little or no theory. Vendor advanced training generally focuses on “data analysis,” which basically means if you see this indication it is this fault or if you exhibit these readings it is that fault. This type of training leads to many equipment condition calls because of a spectral frequency in alarm or an out of tolerance measurement. Now try and answer questions or explain why those indications are present. A thorough understanding of theory enables a user to fully comprehend why those indications are there and exactly what causes them.

In general, a person with an electrical background is selected to conduct electric motor testing. Sometimes it is perceived that the electrical experience will make motor testing easy and effective. Those types of assumptions are what make many motor reliability programs ineffective.

Basic electrical theory is a foundation essential for effective motor testing. Highly experienced electricians with a decade or two should possess the necessary theoretical knowledge. This is true, but- that knowledge is something that may have been gained back in an apprentice program and rarely used since. We have found that to be true with senior Engineers as well. A Simple refresher can shake loose a lot of cobwebs. Think about it? When is the last time you performed an Ohm’s Law calculation?

Answer a couple of questions for me:

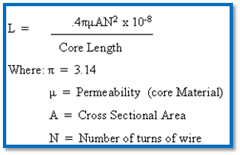

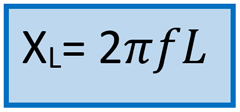

- If I increase measurement frequency what happens to inductance?

-

What kind of circuit am I testing when I am measuring Phase 1 resistance to ground.

- What kind of circuit am I testing when I am reading phase 1 to 2 on a Wye connected motor.

- Reading resistors in parallel and series are like reading what other components?

- Adding another branch in a parallel circuit will do what to Resistance Total and Current?

For someone that is current with their electrical theory, these are easy questions. For someone that hasn’t used or studied any of this for several years or more may answer one or two questions correctly.

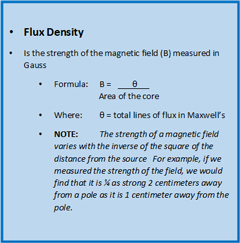

Not only is it essential to review basic electricity, but it is also important to understand how motors are constructed, how they work, how magnetic fields are generated in the stator, and interact with the rotor. How is rotor speed developed and what causes RPM to change during normal operation. Understanding the basics makes diagnostics and trending much easier.

I have some more questions for you:

- What are 8 indications of developing rotor faults?

- If I have shorted turns in a coil of phase 2 on a Wye connected motor how will resistance and inductance be effected?

- What will my energized dynamic spectral and raw data indicate?

- What are the 2 basic types of current spectrums used to analyze motor current?

If you have difficulty answering these questions, you need to consider additional training.

Energized and De-energized electric motor testing provides considerable capability for finding numerous circuit, stator, rotor, power quality, and driven equipment mechanical problems. These technologies are by no means easily mastered, however, with proper training and experience you can become highly effective in no time. The key is optimizing your equipment’s capabilities is by possessing the knowledge necessary to understand all your collected data.

Educational / Professional training provides the theory and operational knowledge to better understand the data that your test instruments provide. These comprehensive courses fully meet the needs of the technician or engineer tasked with motor testing and analysis. If you are not getting the results you expected from your motor reliability program, maybe you are getting what you paid for.