When using IR to inspect electrical systems, it’s good to keep in mind that the faults we’re looking for aren’t always what’s hot. Sometimes it can be the components that appear cool that are the problem.

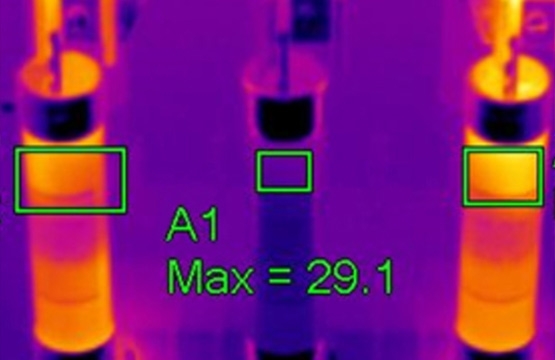

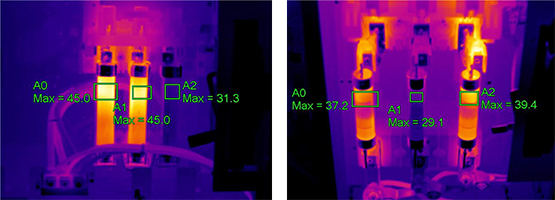

The images shown above are from pumps that were in operation at the time and had been so for quite some time with no apparent signs of problems. You may ask, “how can that be?” In this case, the motor was running with only two phases of voltage and the overcurrent protection should have detected the increase in the current levels and shut it down. This would be a correct assumption if these motors are running across the line (fed directly from the source), but these motors are being operated from a VFD (variable frequency drive). The VFD is generating the missing phase to fill in the needed third phase power for the motor.

The VFD’s in this instance were programmed to ignore the lost incoming phase and to compensate for the loss (against the electrical manager’s specifications). When the pumps faulted on phase loss, the 3rd shift maintenance personnel reprogrammed the VFD to operate with a phase loss. The 3rd shift operations supervisor didn’t want to waste time trying to determine what caused the phase loss, he just wanted the pump running.

Unfortunately, this event was not logged in or recorded for future repairs. Some facilities will use this option when Operations has a higher priority than maintenance. Normal configuration has the VFD fault upon phase loss detection and shuts down the motor it controls. The faults pictured above were discovered during a routine semi-annual IR inspection. There’s no telling how long the phase loss condition was present before it was detected.

This is just one instance of when an electrical component appearing cool was the problem. There are a variety of other causes for components that appear cool. Blown fuses, blown capacitors, dead phase, and broken conductors, to name a few.

Even oversized components will appear cooler than the lower rated items when mixed although they are carrying the same load, such as 60-amp fuse with 40-amp fuses, installed because one of the 40-amp fuses kept faulting. The quick fix (and the wrong fix) was to install a fuse that would not fault, IE the 60-amp fuse. This is sometimes the “corrective action” taken as a short term or troubleshooting measure and not repaired in the proper manner later. Pay attention to overloads, as oversized elements are used for the same purpose, to prevent a motor from tripping on an overload. It more often than not starts as an overload up-size that leads to a fuse up-size.

All energized components should appear warm and some components, such as transformers, contactors, and relays, normally appear warmer. If a piece of equipment should appear warm or hot, and it doesn’t, that can indicate a problem.

Remember, as thermographers, the main thing we are looking for is not just “hot” items, we are looking for things that are different. We’re looking for things that shouldn’t be there, either hot or cool, and sometimes, the component that appears cool is the issue.