When presented with a limited budget, it can be difficult to procure all the necessary assets to support your plant's operational needs as well as the equipment for monitoring your current assets. A good option to enable savings and provide more diverse equipment is to procure used instruments. Having more properly functioning equipment that is older is better than having a few new instruments.

When buying used equipment for your facility it is valuable to know the equipment’s condition. If in good condition, you should verify that it is still supported for repair and software upgrades by the OEM. You are going to spend a good amount of money to purchase, ship, and place this equipment in your facility. We can use conditioning monitoring technologies to help us understand what the condition of the equipment is in when you are buying it. In this article, we are going to discuss two types of conditioning monitoring technologies to evaluate the equipment you are looking to purchase, infrared and offline motor current analysis (MCA). To use these technologies, you will need to make a trip to the job site where the equipment is located to perform the evaluation.

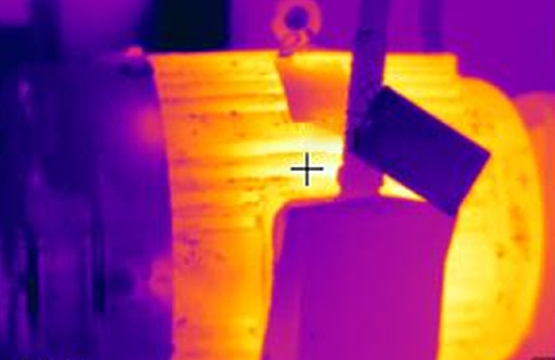

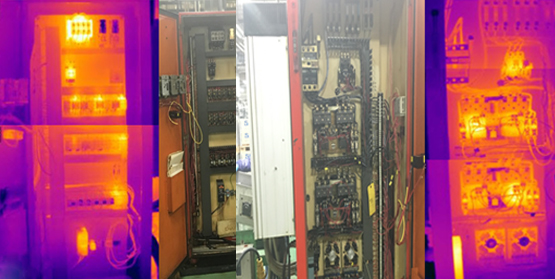

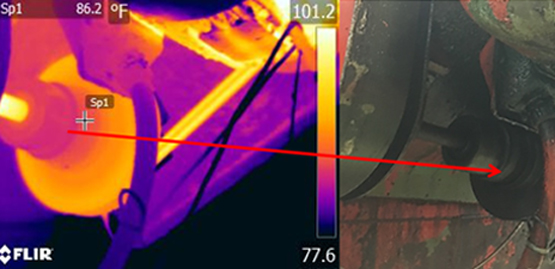

Starting at the power source of the equipment, we can use an infrared camera to go over the electrical system of the equipment. When performing an infrared scan of the electrical system. You want to make sure the equipment is operating at a minimum of a 40% load or higher. This will help to make sure the system is presenting observable and usable data. By using thermography, it is less likely you will miss any problems that might not show up with other types of testing. For example, below is a thermogram of the main electrical components that are controlling a piece of used equipment.

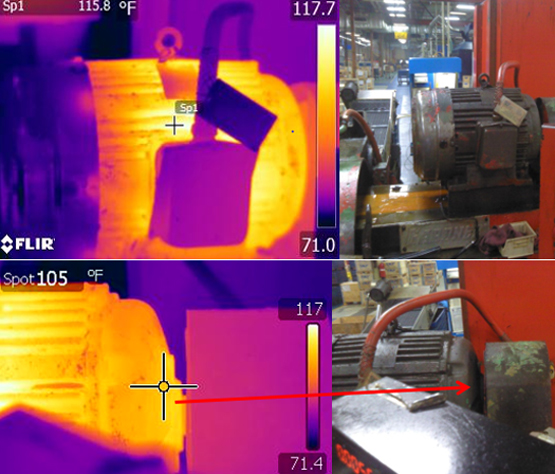

Next, let’s move on to the mechanical portion of the same piece of equipment. Once again, we’ll start with the infrared camera. This inspection will include any moving parts such as shives & belts, any electrical motors, and gearboxes that might be operating different components, and any bearings this equipment might have. Just like performing the electrical scan, you want to make sure this equipment stays under full load as mentioned earlier when looking at the mechanical system for the same reasons. First, we will look at any electrical motors to make sure they are not running hot because that might be a sign of the insulation on the windings getting weak. Therefore, it is vital to know the class of motor and its thermal rating. You will also want to look at the drive end bearing of the motor to look for signs of any problems there.

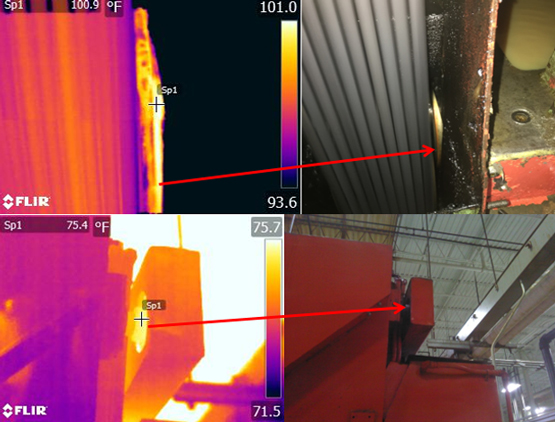

Now we will move on to look at the pully, belts, and shives to look for any signs of wear or excessive heating that may give us clues of any damage to the system.

Then, we will look at the external bearings of the equipment looking for excessive heating that may give us clues of damage to the system.

Finally, we will move on to offline motor circuit analysis (MCA). This will also help us understand the insulation condition of the windings in the electrical motor or motors the equipment has operating on it. Below are the test results of the motor that we have pictured above. We can trend the insulation health and observe changes or degradation in the insulation and take proactive action.

In conclusion, using these conditioning monitoring technologies can help us understand the current condition of the equipment we want to purchase, it can give us a leg up with the seller, and put us in a better financial position when making an offer to purchase their used equipment. In conclusion, using these conditioning monitoring technologies can help us understand the current condition of the equipment we want to purchase, it can give us a leg up with the seller, and put us in a better financial position when making an offer to purchase their used equipment.