In the second part of our three-part series, we will discuss how the condensation of water vapor and vapor retardant barriers are destructive elements that can cause deterioration of materials and failure of building assemblies. There are four different physical mechanisms that can cause moisture to affect surface temperature. We will address the second two of them in this tip.

2. Moisture detection through condensing phase change

Just as the evaporative phase change can be a very dramatic endothermic process, the condensation of water vapor back to water can be just as dramatic as an exothermic process. If condensation is occurring within a wall behind a vapor barrier, then latent heat will be released, and surface warming may occur. This warming pattern is often ignored or misinterpreted as a non-moisture condition (conductive heat loss) by an inspector who thinks water is always identified by detecting “cool areas”. If warm moist air is present either through vapor diffusion or air leakage and migrates to an area below the dew point, then water vapor will start condensing. While this can happen anywhere in the building which has a positive pressure in respect to the outside, it will be particularly prevalent in upper locations which have air leakage pathways to the attic. A thermographer likely will not detect moist warm air exfiltration against an insulated (warm) ceiling, as could occur around a light fixture, yet above there could be significant water deposition in the insulation and into the attic space.

Many inspectors overlook subtle warm patterns, as potential indicators of water presence. Warm areas created by condensation of water vapor may be indicative of a non-drying condition and long-term accumulation of water within an enclosure, which can be much a more serious issue.

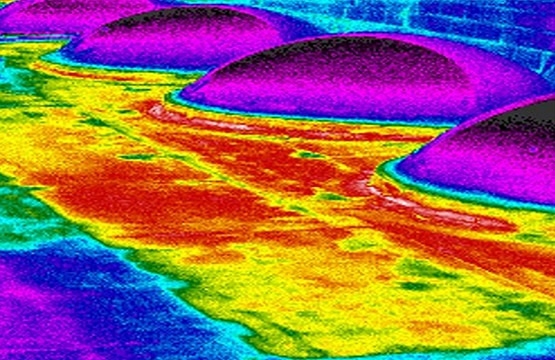

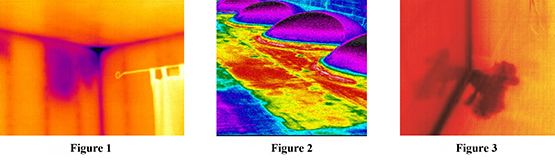

Moisture may be detected by increased conductivity in steady-state heat transfer (figure 1); increased thermal capacitance when undergoing transient heat transfer (figure 2); and through release or absorption of latent heat once undergoing a phase change. In this case (figure 3) evaporative cooling when relative humidity is low.

Water can be the single most destructive element that causes deterioration of materials and failure of building assemblies. It can cause or accelerate corrosion, wood-rot, adhesive dis-bond, masonry spalling, and loss of insulation R value. It is the key element present in the formation of mold and fungi that can lead to indoor air quality problems. The presence of undetected water in a building can affect the value, durability, life-cycle maintenance cost, and occupant health. The challenge facing inspectors is the thermodynamic conditions at the time of the inspection may not be conducive for that thermal detection to take place. While many inspectors have had success using thermal imaging for the otherwise undetectable presence of moisture, the question that begs to be asked is how many times has moisture been present, but since the conditions were not right, the inspector missed it.

Subsurface moisture detection can be detected by infrared thermography only when: its presence affects the surface temperature; the surface is a reliable radiant emitter (high emissivity and non-specular reflector), and the thermal camera is sensitive enough and tuned properly by the inspector to detect such surface temperature difference. Thermographic cameras are extremely sensitive, often able to detect differences less than 0.05ºC (50mK). But while this may create a clearer, more defined pattern when the thermal conditions are right, it is not a viable substitute for moisture detection under poor conditions, when moisture is buried deep within an enclosure—especially with a low permeance surface(s), or when the surface is not a reliable radiant emitter. High sensitivity cameras used under less than ideal conditions can either lead to a large number of false positives, and/or lengthy field time for verification using other methods such as a moisture meter. False negatives lead to credibility issues of both the inspector and the thermographic industry as well as the possibilities of litigation, particularly when mold or other damage associated with moisture is present but not detected.

There are four different physical mechanisms which can cause moisture to affect surface temperature. We have already addressed two of them—evaporative phase change and condensing phase change. We will now discuss the next method.

3. Moisture detection through increased capacitance

Many wall and roof systems have un-intentionally created two or more vapor retardant barriers which inhibits the drying process. This raises the vapor pressure within the assembly and inhibits evaporative cooling as a means of detection. If there are absorbent materials within the enclosure (e.g. wood or glass fiber insulation) then water absorbed by these materials will increase their volumetric thermal capacitance. If the enclosure undergoes a thermal change, such as the sun shines on a roof or south wall—in the northern hemisphere—then wet areas will have a different thermal response time than dry areas (cooler sometime after the sun shines on it, and warmer sometime after the sun has been removed). On sunny days a thermographer should not ignore such thermal irregularities on east, south and west wall areas depending on the time of day. It also means that moisture detection using the capacitance method will usually not be possible on North facing walls, during the night, and on overcast days.