Lubrication/Hydraulic systems are prime candidates for an infrared inspection. With a thermal imager, you can check any number of potential problems including:

The flow path of lubrication fluid

Valves, which sometimes leak by, or in a few instances are not in the proper position, can send fluid moving in the wrong direction. Warmer piping or hoses are an indication of fluid flow.

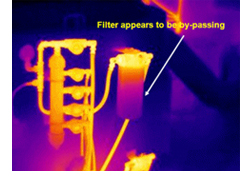

Problems with oil filters

Filters can clog, or by-pass, and these two conditions can be easily verified with the use of infrared. The filter housing should be as warm as the lines feeding it. As seen in the image to the right, when the filter housing is cooler than the rest of the system this is an indication that fluid could be by-passing the filter.

Troubleshooting a hydraulic system accumulator

Accumulators that are not functioning properly can adversely affect the system’s efficiency. An accumulator that is not working correctly can appear cooler than the oil’s normal operating temperature.

Proper hydraulic cylinder operation

While IR is not necessarily the primary tool for this specific application, it may be possible to inspect a hydraulic cylinder with infrared under blow-by conditions to see if you can detect a localized hot spot at the point of failure on the seal. When high-pressure fluid passes between a piston and cylinder wall the resulting friction could cause excessive heat to be generated.

If you apply the basis of thermodynamics, your knowledge of the system, and Think Thermally®. You should be able to work through hydraulic and other types of mechanical systems to discover anomalies and a means to correct them.