Motor testing has been around for as long as motors themselves. Rudimentary testing equipment had been used for decades with varied levels of effectiveness. A little over 30 years ago a specific need was expressed for more focused instruments for electric motor testing. Within a few years several motor tester manufacturers emerged providing many instruments and testing methods.

The advent of electric motor testing technologies brought with it numerous questions to be answered, obstacles to be overcome, procedures to be developed and standards that had to be created to support data collection. In addition, and of utmost importance was data analysis. What does it mean? At what level of unbalance for this parameter is a fault indicated? What data correlates to indicate a development? Slowly and empirically the answers came, obstacles were overcome, standards and procedures developed, and data analysis techniques implemented. Motor testing technicians and engineers were overwhelmed with data and testing techniques.

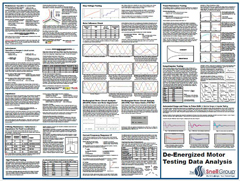

Content Overview: De-Energized Data Analysis

- Utilizing resistance, inductance, and impedance for fault localization to determine the condition of the windings.

- Identify insulation anomalies utilizing data from timed resistance tests, surge/impulse testing, and high potential tests.

- Examples for testing provide visual indications of the symptoms which normally accompany problems in motor performance.

- Helpful illustrations provide a means of determining the rotor and stator relationship by essentially providing a profile representing the effect of rotor impedance on stator inductance utilizing the rotor influence check.

Content Overview: Energized Data Analysis

- Power Quality anomalies provide unique waveform distortions that are provided.

- Voltage and current unbalance can lead to greatly reduced motor longevity. Examples of causes and recommended parameters are provided.

- Use current and impedance percentages to determine connection anomalies, stator anomalies or external parallel circuit faults.

- Information on Harmonics, sequence and identification are provided.

- Localize fault locations using spectral data for Voltage and Current.

- Analyze spectral data for numerous electrical and mechanically induced faults.

- Provides examples of various start circuits and expected start profiles and timing.

- Analyze In-Rush Start Current for connection anomalies, mechanical faults and rotor anomalies.

- Learn 8 ways to identify and correlate rotor faults using energized and de-energized data.

With a fundamental knowledge of motors and motor operation and theory, data analysis can still be quite complex especially when multiple data sets must be correlated to determine a probable fault.

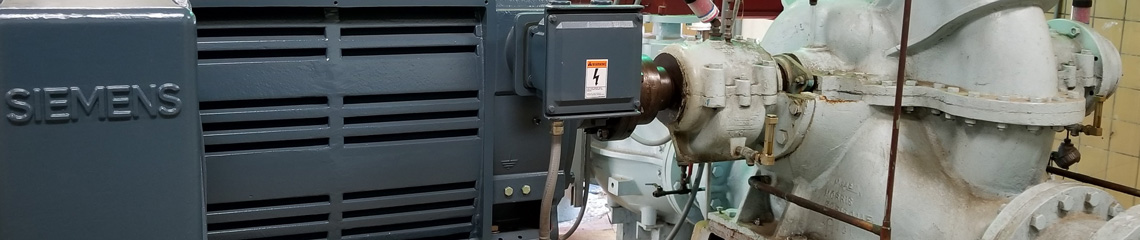

The Snell Group has been conducting motor testing and training for almost two decades. During that time, we have used multiple types of test equipment to test tens of thousands of motor and motor circuits in most types of industrial and commercial facilities. We have developed motor testing industry standards and procedures for applications and safety, developed comprehensive and innovative Electric Motor Testing Training and Certification Courses. We have been pioneers and trendsetters in this technology.

Our latest innovation is a culmination of years of expertise in the field of electric motor testing. We have developed a “Wall Chart” that provides a single reference source to analyze most every anomaly identified while conducting de-energized and/or energized motor testing. This reference asset is packed full of motor analysis information and designed to correlate with Snell’s motor training courses. It is an invaluable data analysis tool for anyone that tests motors, regardless of instrumentation being utilized. Order one today for $149.00 ea. (includes shipping within the US), both charts for $270.00.