My journeys this month have taken me up and down the West Coast performing thermography on electrical systems plus an emergency run to a manufacturing facility.

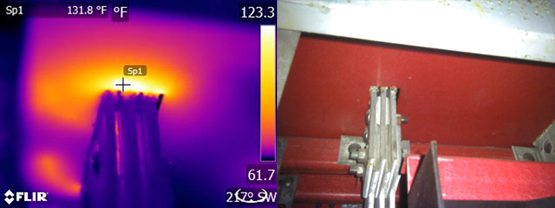

I started off by flying to LA, working, and driving through what they called “The Pineapple Express”. What is “The Pineapple Express” you ask, it was one of the most torrential rainstorms California has seen in a long time. I flew into LAX and grabbed my car in one of the heaviest rains I have ever seen. It lasted the next couple of days but that didn’t stop me from helping several customers with their annual IR inspections. At the first stop I found a very important issue that could have been a disaster for the customer. Hot connection on the A phase of the Incoming electrical line that feeds power to the building. I caught it just in time, the top was locked by the power company so they had to be called in so they could open it up to fix it. They got it fixed the next day after I left.

The next stop wine Country outside of San Fransisco for 2 stops and then a quick flight to Seattle to help another customer.

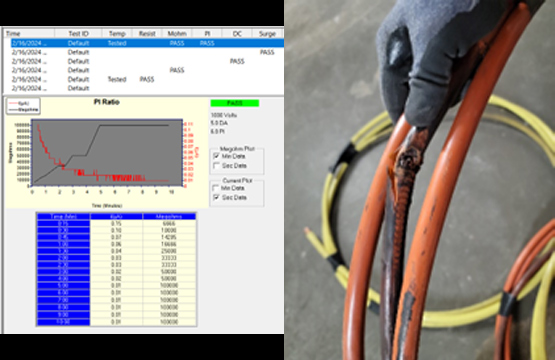

After getting back to my home base in South Dakota I got a call asking for help on a motor that kept tripping out and was interrupting production of a dog food manufacture. The problem was on going for the last 60 days. The motor would run for a week or 2 and then blow the SER’s in the VFD. The electricians would replace the SER’s but it continued to get worse over the next month. After we talked it over, I shipped out my equipment that I would need and headed out the door. Once I arrived at the plant we got right to work. We went right to the electrical room to look at the VFD. We decided to go out to the motor as there was a local disconnect I wanted to test from. With the VFD out of the circuit we can perform our EMT test. The first tests performed were resistance between phases which failed at 5% Res imbalance. Then we tested the motor with a 1-minute Meg, 10 Minute PI Test done at 1,000V DC. The next test performed was the HiPot test done at 2 x line voltage (480) + 1,000V= 1,960V. The test failed because it could not get past 1,610 DCV. I asked the Electricians if the J Box had been opened, they did not know. We opened it up and looked at the taped connections, they all appeared to be fine. The electricians then took the tape off all 3 connections. The pictures below we can see that A and C phases had both been hot, you can see the connections have melted on both phases suggesting they had been at least 1,300F.

After all the T Leads were disconnected I tested the motor all by itself and it tested perfectly fine as you can see at the top of the page.

From there the electricians put new connections on all of the phases. I re-tested the circuit from the local disconnect. After fixing the connections and moving the wires around we could not get past 1,050V. Something else was wrong, I recommended the site pull new wires. The site did pull wires the next day after I left and found this.

A blowout on the B phase of the wires. So in conclusion every phase had an issue causing the VFD to trip out.

Well back to work, tune in next month to see where my journey’s taking me next. Always remember you can give The Snell Group or myself a call. “Our Knowledge. Your Advantage.”