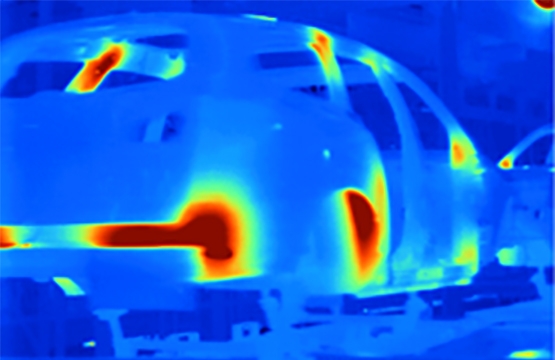

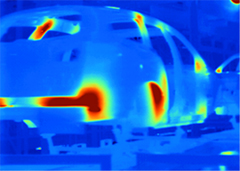

Our fascination with various means of transportation lends itself nicely to the world of thermography. Robust thermography programs were and are instrumental parts of reliability programs at automotive assembly plants throughout the world. Research and development (R&D) and nondestructive testing (NDT) applications are a significant part of the design process. Electrical and mechanical applications have dominated the use of infrared thermography in the automotive industry.

One area in particular, robotic welding, saw frequent inspections of the equipment making spot welds during assembly. In addition to all of the electrical connections available for inspection on robotic welders, water cooled welder tongs or tips could be analyzed for water flow restriction or blockage. Overheating in a welding tip leads to poor quality welds and then failure.

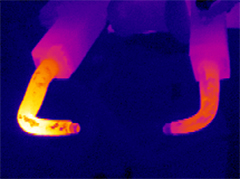

New cars and concept cars are put through an amazing amount of testing prior to release. One aspect where thermography plays a role is in passenger safety and comfort. Proper placement of insulation or reflectors in the floor pan can prevent “hot” foot for a passenger. Confirmation of insulation in the unibody structure can increase passenger comfort and reduce noise levels.

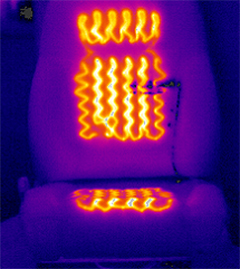

Heated seat testing allows for maximum passenger comfort without the possibility of a painful burn.

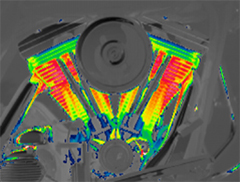

Evaluation of operating temperatures can play a role to ensure there is adequate cooling. Convection plays a key role in cooling. Whether by proper sizing of coolant reservoirs and radiators or appropriate air flow on cooling fins on motorcycles, keeping those engines cool is paramount.

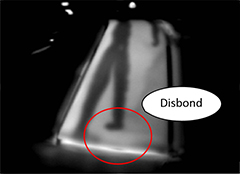

In recent years the use of thermography for nondestructive testing has made tremendous advances. The latest advancements concerning flash thermography have come with advanced analysis techniques. Reconstructing the thermal data is a process where the raw temporal response from each pixel is reconstructed into a mathematical function (Shepard et al., 2002). Not only is system noise reduced, but a variety of analysis techniques become possible, improving the ability to resolve deeper and more subtle subsurface features.

These are but a few samples of some of the great work being done within the automotive industry. The Snell Group has been fortunate to be involved with training and consulting in all aspects of the industry. We hope to see the recent increases in car sales, as compared to a year ago and the investment in strong thermography programs continue go hand in hand.