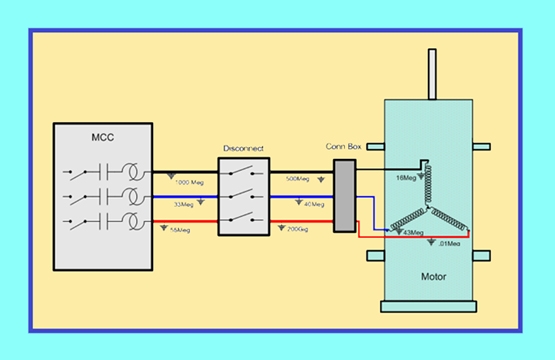

Figure 1 (above). Image displays the various isolated ground readings.

Resistance to ground anomalies can be some of the most difficult motor and motor circuit problems to assess. Given that all motor failure mechanisms result in an increase in motor operating temperature, ultimately insulation problems are the end result. The increased heat thermally degrades and embrittles the winding insulation treatments. Operating stresses, particularly motor starts can result in cracks in the insulation and degradation of resistance to ground.

Identifying a resistance to ground anomaly does not have one answer for maintenance action. The prevailing theory is that if you truly have a failure mode related to resistance to ground that the motor wouldn’t start. This isn’t always the case. The low threshold for acceptable resistance to ground is typically 100 megaohms for motors below 1000 volts. That’s a lot of resistance. It’s not however a magic number, below which motors fail to function. You can have RTG measurements of 50-60 megaohms and the motor will start and run. If this value has significantly degraded or it’s much lower than similar motors in the same area, even these meg-ohm values can indicate a serious developing problem. IEEE recommends that for motor starting that the operational voltage, expressed as a meg-ohm value doubled plus 1000 is the minimum meg value for starting. For a 480V motor that would mean .480Meg x 2= .960 Meg + 1000, so a minimum ground resistance for starting a 480V is 1.960 Meg or round up to 2 meg-ohms.

The RTG values are an indication of both the health and cleanliness of the motor insulation and the insulation integrity of the circuit and cabling. We mentioned overheating as a failure mode for insulation. Another is a natural progression, as insulation ages, it dries and becomes embrittled. Starting and operational stresses cause insulation to crack, and openings in the insulation develop in the form of small holes and voids. In any operating environment, contamination collects on the motor’s windings. As these small fissures develop in the insulation, contamination and moisture can make their way into these openings to the winding conductors themselves. This penetration provides a path for current out of the windings, and since current follows the path of least resistance, it will follow these alternate paths to get between turns, coils, phases and to ground. When it affects ground paths, we read lower than optimal RTG readings.

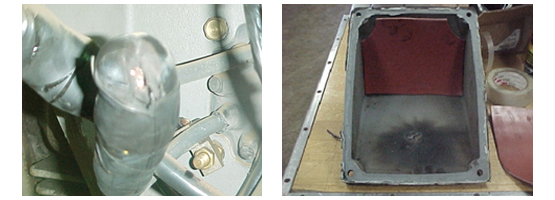

Figure 2. Insulation breakdown arcing to cover. Figure 3. Found performing ground isolation.

When testing at the motor (or maybe when testing an isolated motor)a low RTG reading indicates that I have alternate lower resistance paths to ground for current in the motor windings. This is a failure mode, even though the motor may in fact start and run. In the earliest stages, low RTG readings can indicate that the motor windings need to be cleaned, dipped, and baked, which corrects the insulation failures. If left alone, however, these failure modes can lead to catastrophic failure of the motor, which will require much more correction than a simple clean dip and bake operation. This is true for the motor. What if the ground is in the cabling supplying the motor?

When a ground anomaly is identified when testing from the starter, a process of ground isolation and localization should occur. Test at the next readily assessable location, usually a local disconnect. Test from the load side of the disconnect and determine if the problem is upstream or downstream from the test location. If downstream, move to the motor connection box and isolate the supply cabling. Test the motor. If the problem is in the cabling, it is not as emergent a problem than if it is in the motor. Cable problems can exist indefinitely without further degradation. However, the cabling should be isolated and checked frequently or trended for stability. We have had cabling at customer sites exhibit low and stable grounds for years without change. The prudent thing to do is when you find a problem correct it at the earliest maintenance opportunity. We don’t always have the luxury to do that.

When a ground anomaly is found, isolate it. If it is in the motor and does not meet IEEE thresholds it should be sent out for repair. If a problem is in the cabling, localize the phase, location and, trend for stability or degradation. If degradation is apparent replace the cabling.