In motor testing, the Rotor Influence Check, or RIC as we have come to call it, is one of the tests applied in motor acceptance as well as route-based inspections. It often is used as a troubleshooting method for correlating or identifying failure modes discovered during route-based inspections. It can be performed on induction motors, synchronous and wound rotor motors. It provides us with data to determine stator and rotor faults as well as the ability to determine conditions that may affect the air gap between the rotor and stator. It is one of those tests that we love to hate. It can be tedious and time-consuming with total testing time averaging 30 to 60 minutes for a full rotation. If you can run a motor at load energized testing can provide similar data and more in a few minutes. However, if a motor cannot be run, it can be an extremely useful test providing data no other de-energized test methods can provide.

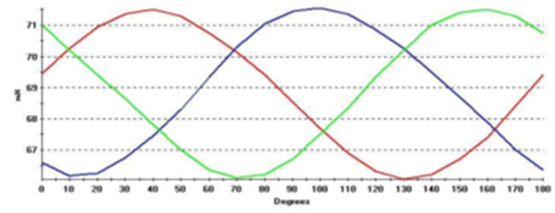

A RIC is performed by rotating the rotor in specific increments, determined by the number of pole groups. Usually, a minimum arc of a pole group will suffice, but under certain circumstances, full rotation will be required. Inductance measurements are taken at each incremental step of the rotor and a plot is generated showing those results. The test signal is low voltage, approximately 5VAC at 1200 HZ. The applied test signal is affected by the residual magnetic field resident in the stator and rotor. That residual magnetism is what influences the test signal and develops the resultant plot. See the image below for an example of a normal RIC plot.

This is the pattern most motor testing analysts expect to see when they perform a RIC test. This is what is referred to as a rotor with influence. This is a common pattern for this cast aluminum rotor motors. Because there are so many of these in service in various sizes, this is a pattern most often seen. However, when testing medium and high voltage copper barred motors, turning the rotor will have minimal influence on the measured stator inductance. This is because these motors are manufactured with higher quality core materials and hold a minimal residual magnetism when they are de-energized.

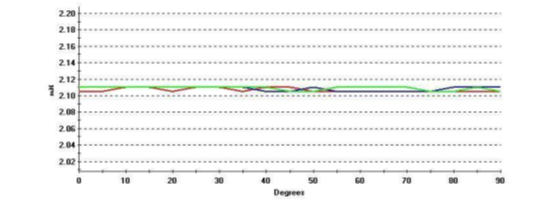

Above is a pattern for a low-influence rotor. As rotor bar defects develop, the inductance will be affected and the sinusoidal shape in the inductance waveforms will become more and more pronounced.

Another type of low-influence rotor is a motor with a large air gap. Older “U” frame motors have such a large air gap that the magnetic field strength is insufficient to affect the stator inductance measurement.

If you’ve never encountered this type of RIC plot before, it can be confusing. With the types of motors described above, this is perfectly normal, so don’t jump to the conclusion that you’ve performed the test incorrectly. Investigate and determine if the motor under test is, in fact, one of the types above and monitor it closely as it remains in service. The changes in the plot for this type of motor are more discrete than in other types, so be careful to watch for them.

For more information on RIC testing as well as other motor testing methods, consider attending one of Snell’s Electric Motor Training courses. Don’t forget to ask us about Electric Motor Testing Certification.