You have heard the phrase “NEW doesn’t necessarily mean good.” How about this one from way back in my high school football days, “Your team is only as good as the worst guy on the bench.” Both these phrases can be applied to your spare motor inventory. Let’s add the word motor to the first phrase and motor reliability to the second; new motor doesn’t necessarily mean good motor; your motor reliability is only as good as your worst motor on the bench, or in the warehouse.

Spares are often overlooked. Even facilities that have programs established to monitor and maintain their motors, often neglect the spares. This can lead to major downtime. Another area of concern is “size matters,” or does it? By that I mean emphasis seems to be placed on motors of higher horsepower, instead of criticality, for condition monitoring and storage maintenance.

There needs to be a comprehensive program to:

1. Test all new and rebuilt motors prior to acceptance as a spare to be placed in inventory.

2. Motors in storage should be tested at least annually as well as having shafts rotated a minimum of quarterly.

Recently, as part of a service availability, I tested a customer’s on-site spares. I found several problems. The customer also had motors stored at an environmentally controlled warehouse maintained by a local motor shop. The shop had been contracted to rotate the shafts and test resistance to ground monthly. When we went to check the motors, we found that none of the motors were connected in a wye configuration to facilitate proper testing. Some of the shafts were blocked and some were heavily saran wrapped, and the shafts could not be turned. I’ll leave it to you to make an integrity assessment.

Statistically, defective spares usually fail within 24 hours of installation. This is true of both electrical and mechanical failure mechanisms.

How do we preclude the above types of incidents? It will take a dedicated program, but-results will more than pay for the investment.

The first step is to establish “Acceptance Testing.” Develop sets of standards for both new and refurbished motors. “ALL” motors get tested before being placed in inventory. “ALL” motors in inventory get tested annually. You may have a fractional horsepower motor that drives a lube oil pump for a critical sleeve bearing motor, or transformer oil pump or cooling water pump. That fractional horsepower motor is every bit as critical as the motor or transformer it supports. So, ALL motors in the warehouse get tested. Motors stored off site should be tested as well. If this storage is contracted and includes periodic testing, then routine unscheduled spot checks should be accomplished. Remember the phrase, “trust but verify?”

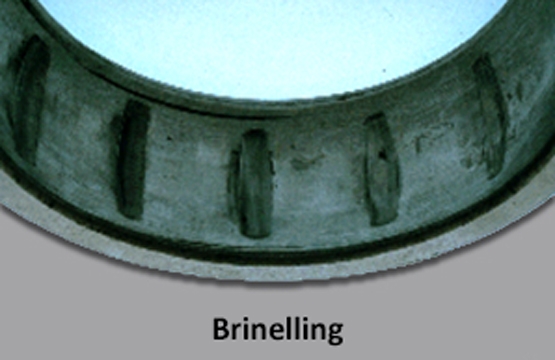

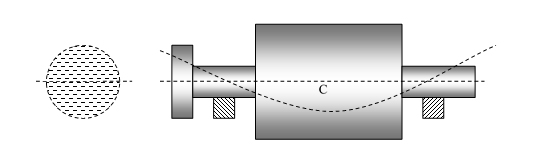

The next step is to establish a program of shaft rotation. Motor rotors are quite heavy and place considerable weight on bearings. Have you ever been in a warehouse and a forklift drives by? Did you feel the slight vibration of the concrete floor? The motor sitting near you on a pallet or shelf felt that same vibration, only it is exposed to those vibrations constantly. This can lead to brinelling. The bearing individual rolling elements will wear in one spot where they contact the bearing race. This will cause excessive friction and lead to rapid failure when the motor gets installed. Another issue is related to the weight of the rotor. Gravity takes its toll on everything including motor rotors that are heavy and only supported by bearings on both ends of the shaft. Motors stored for considerable time periods can enable slight sag of the rotor which may result in rubbing when energized.

At minimum a slight rotor sag will result in an uneven air gap, eccentricity, and result in vibrations that will lead to premature failure.

Spare motor reliability is every bit as important as that of “in service” motors. Remember New motor does not mean good motor and your reliability is only as good as your worst motor in the warehouse.