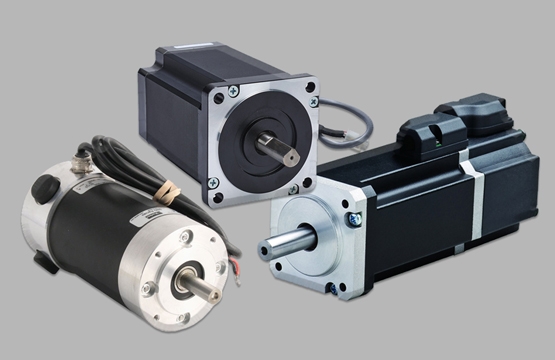

One of the more common questions asked by reliability workers with regard to Electric Motor Testing (EMT) is the type of electric motors that can benefit from condition monitoring testing. Obviously, various industries employ different sizes and types of motors. Some facilities would consider a 25HP motor to be enormous, while others have 250HP plus higher motors, and still, other facilities might only employ fractional horsepower motors. Sometimes overlooked as a candidate for EMT inspection are servos and stepper motors.

So, what are they exactly? A stepper motor is a brushless DC motor that divides its full rotation into equal steps, hence the name. Not especially imaginative but pretty accurate. A typical brushed DC motor rotates continuously when current is applied to its windings, because the current is evenly applied. In a stepper motor, there are individual sets of windings with teeth on them. To begin rotation, one set of windings is energized, then depending on the desired amount of movement, another set of windings is energized while the first is de-energized, allowing the teeth of the energized windings to pull the rotor into alignment with it. A stepper motor requires a microcontroller to determine the size of the steps and how many steps in a single operation it takes. By comparison, a servo can be a brushed DC motor, a brushless DC motor or even an AC induction motor that has an electronic feedback mechanism that is external to it. Which type of motor is used for a particular servo application is usually dependent upon the amount of rotational power that is required.

What makes a servo motor a servo motor is its encoder. There are different types of encoders, but they can typically be broken down as either absolute encoders or incremental encoders. A servo motor can be tested like any other motor of its particular type. Phase to phase resistance, capacitance to ground, phase to phase inductance are all tests that can be performed on these. A stepper motor has a particular internal mechanism that allows it to operate in steps, but it is essentially just a DC motor. As such, both servos and stepper motors can benefit from EMT just like other motors can.

If your reasoning for not employing EMT is that you can’t use it on your servos and stepper motors, take heart. You can, in fact, find the same modes of failure in these as you can every other motor in your facility.