I have been instructing IR with The Snell Group for a number of years, and it’s a very rewarding job. I love the moment in class when I see a student’s look of excitement that indicates they have just learned something they did not know before that moment.

One of the first things I try to pass on to a class is to fight the urge to rush a snap judgment on a thermal image. It is human nature to want to solve a problem faster than the next guy. Quick and uninformed problem solving usually leads to an improper diagnosis.

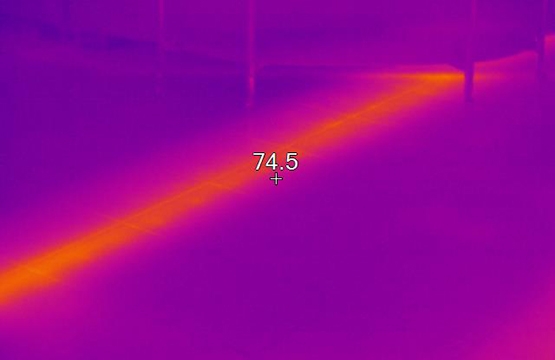

When diagnosing an IR image many questions should be asked, and properly answered before labeling the cause of a thermal anomaly. The first question to ask should be, “Is this an image of a problem, or is this a normal thermal signature for this object?” I can’t imagine anything would not be considered a normal thermal pattern.

If the thermal pattern is considered abnormal, then the task becomes to find out why it is abnormal. This is where I’m going to raise some eyebrows of some readers. Once the thermal pattern is considered to be incorrect, the job of the thermagrapher is complete. The thermographer should not try to diagnose the problem. Now I know some of you want to hit the back button on your browser right now, but hear me out first.

The role of the thermographer is to capture thermal images of problems. I can take any individual that has absolutely no electrical or mechanical experience, and have that person doing limited thermography in a day or two. All I need is to first teach them how to operate a thermal imager. Then, I would show the person a thermal image of a widget that is considered normal. I could set them free in a building full of these widgets and tell them to find the ones that don’t look thermally like the control image. When he or she finds the widget that is not thermally like the control image, I would then ask him or her, “What is causing the anomaly?” This is where the process breaks down. With no background knowledge about a widget’s inner workings, the person is clueless as to the cause of the problem.

Diagnosing a thermal anomaly requires other questions to be asked with corresponding correct answers.

For electrical problems, one should ask some of the following questions:

- Is the connection lose

- Is the connection corroded?

- Is the connection over tightened?

- Is the connection the wrong size?

- Is the connection overloaded?

- Is the connection improperly cooling?

- Is there a load balance issue?

- Is there a harmonics issue?

For mechanical questions, similar questions could be asked:

- Is the component out of alignment?

- Is the component properly lubricated?

- Is there metal on metal contact within or around the component?

- Is the component over pressurized?

- Is the component overloaded?

- Is there a bearing failure within the component?

- Is there a clogged or plugged line within, or going to, the component?

These are a few of the many questions you should be asking. As you can see, there are other tools and skill sets that must be employed in order to properly diagnose the cause of an abnormal thermal pattern. If you must try to solve what is causing a thermal anomaly without further investigation, I would suggest you list everything that could possibly cause the thermal issue in the image. Snap diagnostics can lead to wasted time, money, and a downgrade in your credibility. Always ask questions, take your time, and don’t rush to judgment!