Motor Current Signature Analysis (MCSA), is a highly effective method for identifying many mechanical faults. Success will be directly related to the amount and accuracy of collected drive train data. Vendor software’s vary in the amount of drive train information, which can be included in the database. They also vary in capability of automated fault frequency identification. It is highly recommended that you conduct a “drive train map,” that will include all applicable information, such as; coupling type, pulley or sheave diameters, number of belts and belt lengths, sheave pitch diameters, number of fan or impeller blades, gear box ratio’s, bearing type, number of rolling elements, contact angles etc.

If all of the information is not available, an effective alternative is to map the RPM at each stage of the drive train. Perform the mapping when the motor is at normal load, then set up alarm band frequency parameters based on load variance. When performing analysis, you can then refer to the annotated parameters and determine what drive component is the likely cause of the suspect frequency.

Most mechanical anomalies will cause an increase in the run speed spectral peak.

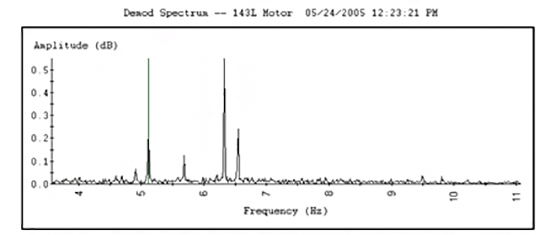

Evaluating Belt Frequencies: Belt related faults are easily displayed in a current spectrum. They will always be less than the RPM. Because of this they will readily show in the low frequency spectrums. Identifying belt problems is especially easy as there are only a few things that can be anomalous with belt driven systems and all of the problems result in similar spectral representation. Belt faults include:

- looseness

- excessive tension

- misaligned sheaves

- eccentric sheave

- bad belt seam

- dished belt

When belt frequencies are present, the best resolution is to check belt tension and alignment of the sheaves. After alignment is completed and belt frequencies are still present, the problem is one of three things:

- defective belt

- eccentric driver sheave

- eccentric driven sheave

Belt Frequency is calculated by:

The pulley diameter is the diameter to where the belt rides on the pulley, referred to as the pitch diameter.

If the belt length is not available or access for precise measurement is not possible other calculations can be made to determine the belt length. You will need to measure the pulley or sheave diameters for the driver and driven sheaves and the center to center distance between the sheaves. Run speed must also be known.

MCSA provides an expedient method for identifying problems with belt driven equipment. Use of MCSA is also provides the capability of identifying many other electrical and mechanical problems. For more information on MCSA and many other motor testing methods, consider attending one of Snell Groups Electric Motor Testing formal training courses.