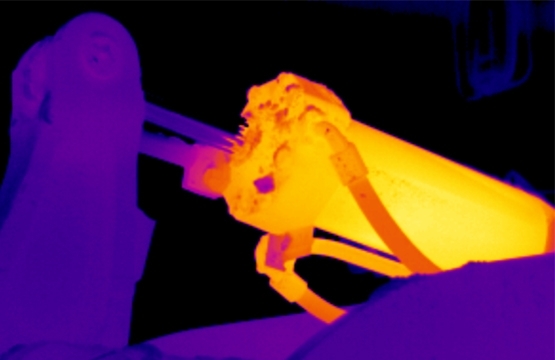

Many of the folks I work with in classes or in the field have electrical backgrounds. Most electrical inspections are “exception based”. That is, when you see something that’s not right, it is a problem and it is reported. Mechanical inspections on the other hand can be quite difficult depending on what type of equipment one is inspecting. Looking at pumps can be a challenge; the different drive systems alone can raise a number of questions as to what is normal, critical, and the basic question of what the failure modes are with this piece of equipment.

Is the drive in line or offset? Is the impeller center hung or overhung? What type of pump is it? Positive displacement, centrifugal, gear, variable cavity, piston, or any number of other types? What about the power to drive the pump? Is the power from electrical, steam, water, vacuum, hydraulic, or even gravity? What kind of material is the pump moving? Is the material hot or cold? Can the material get hot or should it stay cool? Perhaps the other way around?

We may not have all the answers, but we need to know where to get the answers, or who to ask. We may not have all the questions. However, our knowledge of how heat moves and asking what could be creating a certain pattern in a device helps to obtain the answers we need. We can determine what a “normal” condition is and look for the differences.

Are there rules of thumb to use? The only answer I can give is to see what the manufacturers of certain products have listed as “critical temperatures” and use them as a guide. Keeping in mind that generally the surface temperature is going to be lower than where the heat is being generated internally.

Some resources that have provided some of that information:

- Lubrication suppliers

- Drive belt suppliers

- NEMA (motor insulation temps)

- Bearing manufactures (critical not to exceed temp by materials)

- Reliability publications

The thing to keep in mind is these are starting points; your “critical points” will have to be tailored and defined to suit your application. More often than not, we are looking for differences between identical or similar devices. Start by asking the old question, “Which of these things does not look like the others?” and then ask “Why is it different?”